Equipment Features

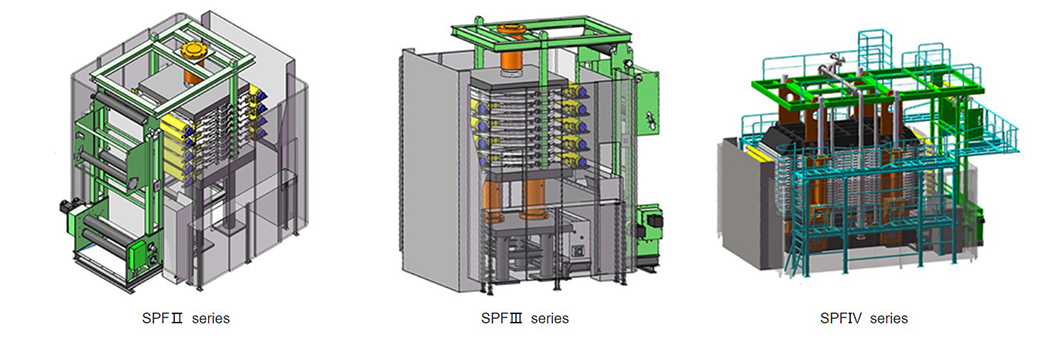

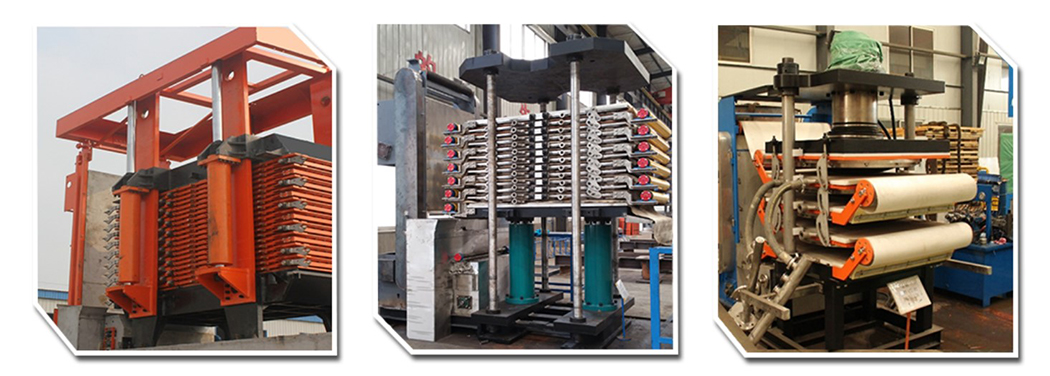

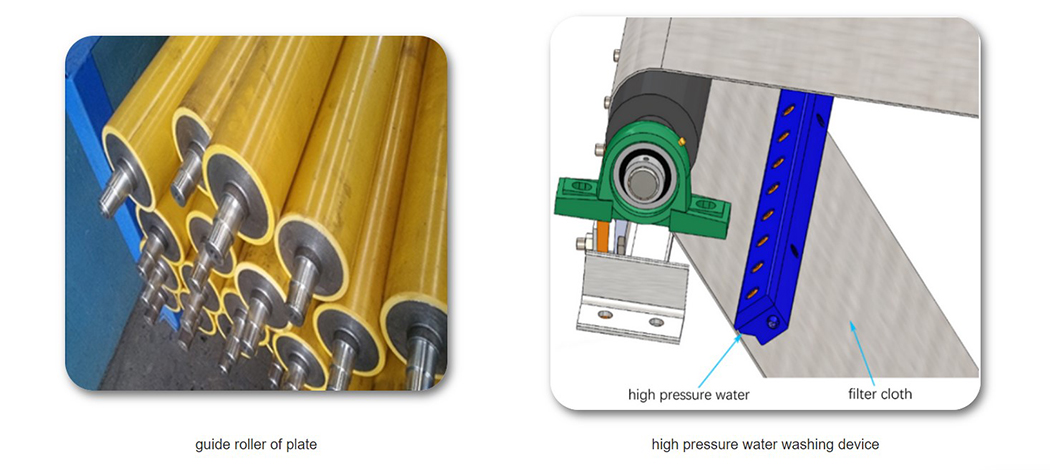

use stacked structure for the plates, use auxiliary guide device to make the operation become more stable.

● Integrate filtering, extrusion, washing, air-drying, cake discharging and cloth washing together.

● The extrusion pressure up to 1.6MPa, it widely used in the field which has different requirements for cake moisture.

● 4.use hydraulic drive control system, make the operation stable and with low power consumption.

● Integrate PLC, HMI and instruments control system etc. intelligent together, it makes filter more efficient and easier.

● Use high pressure water cleaning device to make the cloth washing more effective.

● Design with circular chamber, the structure more rational, the efficiency more prominent.

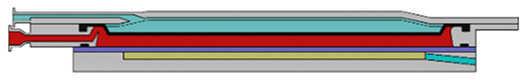

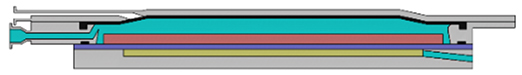

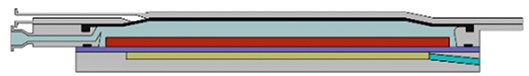

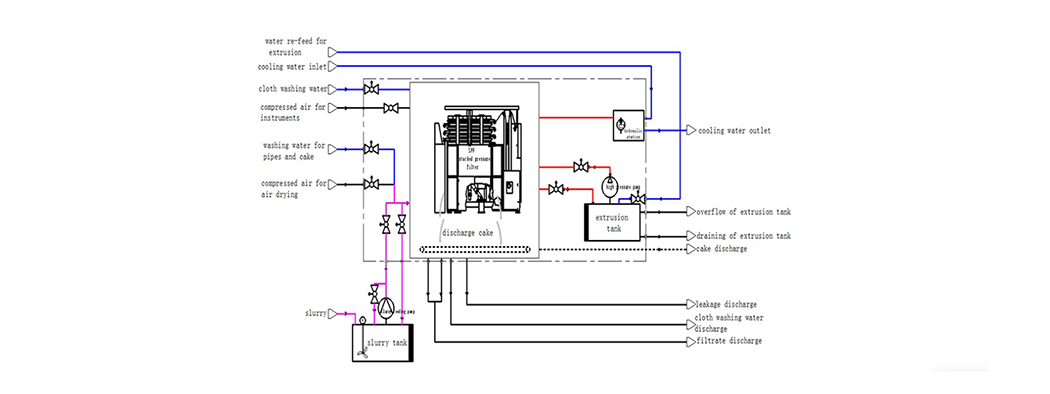

Operating Principle

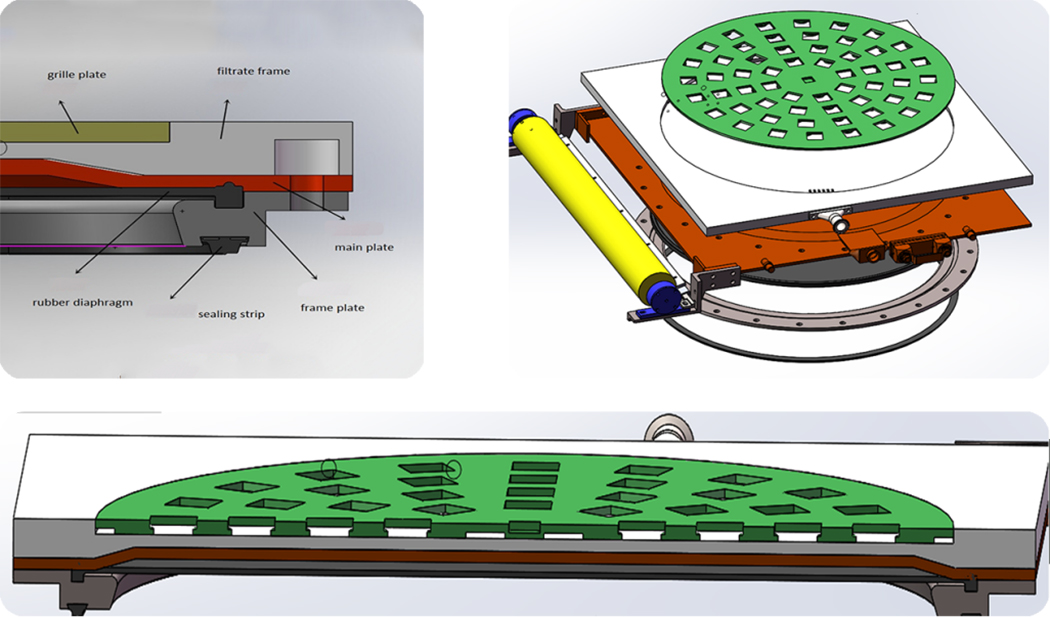

1、Filtering: when the plates group closed, pump the slurry to filter, use distributed hose to feeding slurry to each slurry chamber, and filtrate pass through the cloth to filtrate frame and discharge out, the solid formed a cake on cloth surface.

2、Extrusion: high pressure water fed into upper chamber of rubber diaphragm, make the diaphragm expand and extruding the cake and the liquid will be extruding out from cake.

3、Cake washing: washing water feeding into slurry chamber through distributed hose cover on the cake completely,under the pressure, the washing water pass through the cake and cloth to discharge out.

4、Air drying: compressed air through distributed hose feeding into slurry chamber and pressing rubber diaphragm, make the high-pressure water in the rubber diaphragm to discharge out, and the compressed air pass through cake and take liquid out to decrease the cake moisture to the lowest level.

5、Cake discharging: when finished the air-drying process, open the plates group, drive system makes the cloth running and the cake discharge out on the two sides of filter at the same time.

Note: Please according to the real using condition to adjust the times of extrusion and air- drying process.

Process Flow Diagram

Equipment Series

Technical Specification

| Model/VSPFⅠ | VSPFⅠ-1 | VSPFⅠ-2 | VSPFⅠ-3 |

| Filter area/m2 | 1 | 2 | 3 |

| Plate size/mm | 0.5m2/layer | ||

| Plate qty/layer | 2 | 4 | 6 |

| Length/m | 2.5 | ||

| Width/m | 1.5 | ||

| Height/m | 2 | 2.2 | 2.5 |

| Weight/T | 8 | 9 | 10 |

| Hydraulic station power/KW | 7.5 | ||

| Extrusion pump head/m | 167 | ||

| Extrusion pump flowrate m3/h | 8 | ||

| Extrusion pump power/KW | 7.5 | ||

Auxiliary Equipment Data

| Pipe washing pump head/m | 70 | ||

| Pipe washing pump flowrate m3/h | 10 | ||

| Cloth washing pump head/m | 70 | ||

| Cloth washing pump flowrate m3/h | 10 | ||

| Slurry feeding pump head/m | 70 | ||

| Slurry feeding pump flowrate m3/h | According to slurry data to choose | ||

| Air drying pressure/Mpa | 0.8 | ||

| Air compressor flowrate for air drying m3/min | 0.5 | 1 | 1.5 |

| Air drying tank volume/m3 | 1 | 2 | 3 |

| Air pressure for instruments/Mpa | 0.7 | ||

| Air compressor flowrate for instruments m3/min | 0.3 | ||

| Instruments air tank volume/m3 | 0.5 | ||

| Remark: the equipment outline dimension is basic size, but not details size, so this size just for reference. Different material of plate, the filter will have different height and weight. Auxiliary equipment data just for reference, it will change by filter performance in different slurry. | |||

Technical Specification

| Model | VSPFⅡ-3 | VSPFⅡ-6 | VSPFⅡ-9 | VSPFⅡ-12 | VSPFⅡ-15 | VSPFⅡ-18 | VSPFⅡ-21 | VSPFⅡ-24 |

| filter area/m2 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 |

| plate size/mm | 1.5m2/layer | |||||||

| plate Qty/layer | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| length/m | 3.7 | |||||||

| width/m | 4.1 | |||||||

| height/m | 2.6 | 2.8 | 3.2 | 3.7 | 4.2 | 4.6 | 5.1 | 5.5 |

| weight/T | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| hydraulic station power/KW | 11 | |||||||

| Extrusion pump head/m | 28 | |||||||

| Extrusion pump flowrate m3/h | 136 Note: if extrusion pressure more than 1.3MPa, this data is 164 | |||||||

| Extrusion pump power/KW | 11 Note: if extrusion pressure more than 1.3MPa, this data is 15 | |||||||

Auxiliary Equipment Data

| Pipe washing pump head /m | 68 | |||||||

| Pipe washing pump flowrate m3/h | 20 | |||||||

| Cloth washing pump head/m | 70 | |||||||

| Cloth washing pump flowrate m3/h | 12 | |||||||

| Slurry feeding pump head/m | 70 | |||||||

| Slurry feeding pump flowrate m3/h | According to slurry data to choose | |||||||

| Air drying pressure/Mpa | 0.8 | |||||||

| Air compressor flowrate for air drying m3/min | According to slurry data to choose | |||||||

| Air drying tank volume/m3 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Air pressure for instruments/Mpa | 0.7 | |||||||

| Air compressor flowrate for instruments m3/min | 0.5 | |||||||

| Instruments air tank volume/m3 | 1 | |||||||

| Remark: the equipment outline dimension is basic size, but not details size, so this size just for reference. Different material of plate, the filter will have different height and weight. Auxiliary equipment data just for reference, it will change by filter performance in different slurry. | ||||||||

Technical Specification

| Model VSPFⅢ | VSPFⅢ-18 | VSPFⅢ-24 | VSPFⅢ-30 | VSPFⅢ-36 | VSPFⅢ-42 | VSPFⅢ-48 | VSPFⅢ-54 | VSPFⅢ-60 | VSPFⅢ-66 |

| filter area/m2 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 |

| plate size/mm | 3.0m2/layer | ||||||||

| plate Qty/layer | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 |

| length/m | 5.1 | ||||||||

| width/m | 5.5 | ||||||||

| height/m | 4.3 | 4.5 | 4.9 | 5.4 | 5.8 | 6.3 | 6.8 | 7.2 | 7.7 |

| weight/T | 31 | 33 | 35 | 37 | 39 | 41 | 43 | 45 | 47 |

| hydraulic station powerKW | 22 | ||||||||

| Extrusion pump head/m | 40 | 55 | |||||||

| Extrusion pump flowrate m3/h | 136 Note: if extrusion pressure more than 1.3MPa, this data is 162 | 135 Note: if extrusion pressure more than 1.3MPa, this data is 166 | |||||||

| Extrusion pump power/KW | 15 Note: if extrusion pressure more than 1.3MPa, this data is 18.5 | 22 Note: if extrusion pressure more than 1.3MPa, this data is 30 | |||||||

Auxiliary Equipment Data

| Pipe washing pump head/m | 65 | ||||||||

| Pipe washing pump flowrate m3/h | 26 | ||||||||

| Cloth washing pump head/m | 70 | ||||||||

| Cloth washing pump flowrate m3/h | 16 | ||||||||

| Slurry feeding pump head/m | 70 | ||||||||

| Slurry feeding pump flowrate m3/h | According to slurry data to choose | ||||||||

| Air drying pressure/Mpa | 0.8 | ||||||||

| Air compressor flowrate for air drying m3/min | According to slurry data to choose | ||||||||

| Air drying tank volume/m3 | 8 | 10 | 10 | 12 | 12 | 15 | 15 | 20 | 20 |

| Air pressure for instruments/Mpa | 0.7 | ||||||||

| Air compressor flowrate for instruments m3/min | 0.5 | ||||||||

| Instruments air tank volume/m3 | 1 | ||||||||

| Remark: the equipment outline dimension is basic size, but not details size, so this size just for reference. Different material of plate, the filter will have different height and weight. Auxiliary equipment data just for reference, it will change by filter performance in different slurry. | |||||||||

Technical Specification

| Model VSPFⅣ | VSPFⅣ-60 | VSPFⅣ-72 | VSPFⅣ-84 | VSPFⅣ-96 | VSPFⅣ-108 | VSPFⅣ-120 | VSPFⅣ-132 | VSPFⅣ-144 | VSPFⅣ-156 | VSPFⅣ-168 |

| Filter area/m2 | 60 | 72 | 84 | 96 | 108 | 120 | 132 | 144 | 156 | 168 |

| Plate size/mm | 6m2/layer | |||||||||

| Plate Qty/layer | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| Length/m | 7.1 | |||||||||

| Width/m | 5.5 | |||||||||

| Height/m | 5.4 | 5.8 | 6.2 | 6.6 | 6.9 | 7.2 | 7.6 | 7.9 | 8.3 | 8.6 |

| Weight/T | 92 | 96 | 100 | 104 | 108 | 112 | 116 | 120 | 124 | 128 |

| Hydraulic station power/KW | 30 | 37 | ||||||||

| Extrusion pump head/m | 110 | 150 | ||||||||

| Extrusion pump flowrate m3/h | 126 Note: if extrusion pressure more than 1.3MPa, this data is 168 | 128 Note: if extrusion pressure more than 1.3MPa, this data is 162.5 | ||||||||

| Extrusion pump power/KW | 37 Note: if extrusion pressure more than 1.3MPa, this data is 45 | 55 Note: > 1.3MPa, this data is 75 | ||||||||

Auxiliary Equipment Data

| Pipe washing pump head/m | 72 | |||||||||

| Pipe washing pump flowrate m3/h | 36 | |||||||||

| Cloth washing pump head/m | 70 | |||||||||

| Cloth washing pump flowrate m3/h | 20 | |||||||||

| Slurry feeding pump head/m | 70 | |||||||||

| Slurry feeding pump flowrate m3/h | According to slurry data to choose | |||||||||

| Air drying pressure/Mpa | 0.8 | |||||||||

| Air compressor flowrate for air drying m3/min | According to slurry data to choose | |||||||||

| Air drying tank volume/m3 | 20 | 20 | 25 | 30 | 35 | 35 | 40 | 40 | 45 | 45 |

| Air pressure for instruments/Mpa | 0.7 | |||||||||

| Air compressor flowrate for instruments m3/min | 1 | |||||||||

| Instruments air tank volume/m3 | 2 | |||||||||

| Remark: the equipment outline dimension is basic size, but not details size, so this size just for reference. Different material of plate, the filter will have different height and weight. Auxiliary equipment data just for reference, it will change by filter performance in different slurry. | ||||||||||

Application Fields

It is widely used in urban sewage, textile printing and dyeing, electroplate, papermaking, leather, brewing, food processing, coal washing, petrochemical industry, chemistry, metallurgy, mineral separation, pharmacy, ceramic industry sludge dewatering and so on, also use in industry production solid-liquid separation or liquid leaching process.

| No. | Material name | Feed solidity (g/l) | Extrusion water ressure(MPa) | Cake thickness (mm) | Cake moisture (%) | Capacity kg/m2.h |

| 1 | 4A-zeolite | 150~295 | 1.4 | 35 | 19~22 | 190~200 |

| 2 | Sulfuret | ≈50 | 1.2 | 30 | 30 | 120 |

| 3 | Lead | ≈50 | 1.2 | 30 | 15~20 | 35 |

| 4 | Copper slag | 600 | 1.6 | 40 | 8~9 | 310 |

| 5 | Waste water sulphate | 80 | 1.6 | 45 | 28~35 | 120~175 |

| 6 | Calcination gold tailings | 300 | 1.6 | 35 | 14~18 | 300~340 |

| 7 | Superfine aluminum hydroxide | 15~20% | 1.6 | 20 | 29.5~32 | 65 |

| 8 | Cu-Ni concentration | 66.7 | 1.6 | 30 | 9.78 | 257 |

| 9 | Copper concentration | 45~50 | 1.6 | 35 | 7.6 | 360 |

| 10 | Ni concentration | 45~50 | 1.6 | 30 | 8 | 300~400 |

| 11 | Tantalum-niobium smelt | 1.6 | 20~25 | 200 | ||

| 12 | Coal slime | 30~35% | 1.6 | 30 | 16~17 | 300 |

| 14 | Gold tailings after flotation | 20~30% | 1.6 | 35 | 12~18 | 300 |

| 15 | Mannitol | 1.5 | 12 | 35 | ||

| 16 | Zinc oxide powder | 57% | 1.6 | 18 | 20 | 90 |

| 17 | Leaching residue of zinc oxide | 50% | 1.6 | 10 | 18~20 | 70 |

| 18 | Sulphur concentrate | 10% | 1.6 | 20 | 25~35 | 200 |

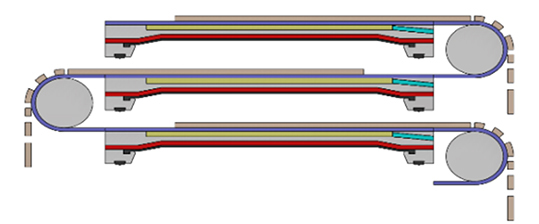

Equipment Structure

Plate Group Structure

Manufacture Pictures

Main Parts

Using Site