| Model | Power (kW) | Cavity Type | Max Feeding Size (mm) | Throughput (t/h) if Crusher Running at CSS (mm) | ||||||||||

| VSH820 | 90 | 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 51 | ||

| EC | 135 | 55 | 100 | 105 | 115 | 120 | 130 | 145 | ||||||

| C | 90 | 60 | 405 | 110 | 120 | 125 | 135 | 80 | ||||||

| M | 65 | 50 | 85 | 90 | 90 | 70 | ||||||||

| MF | 50 | 40 | 75 | 80 | 80 | 60 | ||||||||

| F | 38 | 60 | 60 | 65 | 55 | 45 | ||||||||

| EF | 28 | 30-40t/h with 80% less than 4.5-5.5mm | ||||||||||||

| 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 51 | ||||

| EC | 190 | 125 | 170 | 185 | 196 | 210 | 240 | 240 | ||||||

| C | 145 | 85 | 150 | 165 | 175 | 185 | 200 | 225 | 170 | |||||

| VSH830 | 160 | MC | 115 | 65 | 160 | 175 | 185 | 200 | 210 | 165 | ||||

| M | 90 | 75 | 100 | 150 | 165 | 175 | 185 | 175 | 120 | |||||

| MF | 75 | 70 | 120 | 130 | 145 | 145 | 130 | 105 | ||||||

| F | 50 | 90 | 95 | 100 | 110 | 120 | 120 | 110 | 90 | |||||

| EF | 35 | 70-90t/h with 80% less than 5-5.6mm | ||||||||||||

| 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 51 | ||||

| EC | 215 | 200 | 276 | 294 | 313 | 357 | 395 | |||||||

| C | 175 | 101 | 218 | 292 | 312 | 332 | 378 | 335 | ||||||

| VSH840 | 250 | MC | 140 | 122 | 262 | 282 | 301 | 320 | 328 | 242 | ||||

| M | 110 | 187 | 278 | 298 | 318 | 339 | 281 | 194 | ||||||

| MF | 85 | 114 | 227 | 245 | 263 | 281 | 299 | 248 | ||||||

| F | 70 | 135 | 176 | 191 | 206 | 221 | 236 | 251 | 208 | |||||

| EF | 38 | 100-125t/h with 80% less than 6-7.5mm | ||||||||||||

| 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 51 | ||||

| EC | 275 | 177 | 338 | 436 | 464 | 547 | 605 | 511 | ||||||

| C | 215 | 190 | 367 | 480 | 501 | 582 | 643 | 353 | ||||||

| VSH860 | 315 | MC | 175 | 253 | 426 | 455 | 484 | 552 | 499 | |||||

| M | 135 | 295 | 440 | 470 | 500 | 502 | 403 | |||||||

| MF | 115 | 192 | 369 | 396 | 423 | 450 | 451 | 363 | ||||||

| F | 85 | 304 | 328 | 352 | 376 | 400 | 401 | 323 | ||||||

| EF | 65 | 293 | 316 | 298 | 290 | |||||||||

| 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | 57 | 70 | ||||

| EC | 300 | 588 | 849 | 968 | 1070 | 1172 | 1291 | 1393 | 1331 | |||||

| C | 240 | 406 | 636 | 893 | 1018 | 1125 | 1232 | 1357 | 1464 | 1286 | ||||

| VSH870 | 500 | MC | 195 | 440 | 723 | 837 | 954 | 1055 | 1155 | 1272 | 1373 | 1206 | ||

| M | 155 | 563 | 786 | 836 | 953 | 1054 | 1154 | 1271 | 1372 | 1098 | ||||

| MF | 100 | 424 | 716 | 765 | 814 | 928 | 942 | 789 | 702 | |||||

| F | 90 | 395 | 656 | 704 | 752 | 800 | 912 | 857 | 718 | |||||

| EF | 80 | 517 | 558 | 598 | 639 | 680 | 775 | 128 | 669 | |||||

| 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | 57 | 70 | ||||

| EC | 370 | 459 | 1309 | 1446 | 1584 | 1745 | 1883 | 2181 | ||||||

| C | 330 | 397 | 774 | 1404 | 1552 | 1700 | 1873 | 2020 | 2140 | |||||

| VSH880 | 750 | MC | 300 | 513 | 852 | 1232 | 1404 | 1552 | 1700 | 1873 | 2020 | 1739 | ||

| M | 230 | 312 | 670 | 951 | 1106 | 1261 | 1394 | 1526 | 1681 | 1814 | 1564 | |||

| MF | 160 | 204 | 514 | 690 | 921 | 980 | 1117 | 1235 | 1352 | 1490 | 1607 | 1170 | ||

| F | 120 | 289 | 669 | 838 | 895 | 952 | 1085 | 1165 | 1051 | 827 | 625 | |||

| 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | 64 | ||||

| VSH885 | 750 | EFX | 100 | 423 | 666 | 715 | 763 | 812 | 926 | 994 | 896 | 705 | ||

| EF | 85 | 246 | 585 | 631 | 678 | 724 | 770 | 878 | 970 | 1063 | 1170 | 862 | ||

| EEF | 75 | 475 | 564 | 608 | 653 | 697 | 742 | 846 | 855 | 761 | 580 | |||

| Model | Power (kW) | Cavity Type | Max Feeding Size (mm) | Nominal capacity in t/h with crusher running at CSS (mm) | ||||||||||

| 16 | 19 | 22 | 25 | 29 | 32 | 35 | 38 | 41 | 44 | 51 | ||||

| VSS820 | 90 | EC | 240 | 110 | 123 | 142 | 151 | 145 | 132 | |||||

| C | 200 | 77 | 85 | 105 | 110 | 131 | 133 | |||||||

| VSS830 | 160 | EC | 360 | 151 | 161 | 175 | 193 | 243 | 285 | 300 | 250 | |||

| C | 300 | 170 | 182 | 203 | 256 | 273 | 295 | 305 | ||||||

| VSS840 | 250 | EC | 450 | 273 | 323 | 345 | 356 | 447 | ||||||

| C | 400 | 291 | 335 | 363 | 395 | 415 | 375 | |||||||

| VSS860 | 315 | EC | 560 | 385 | 464 | 535 | 647 | |||||||

| C | 500 | 335 | 418 | 535 | 620 | 683 | ||||||||

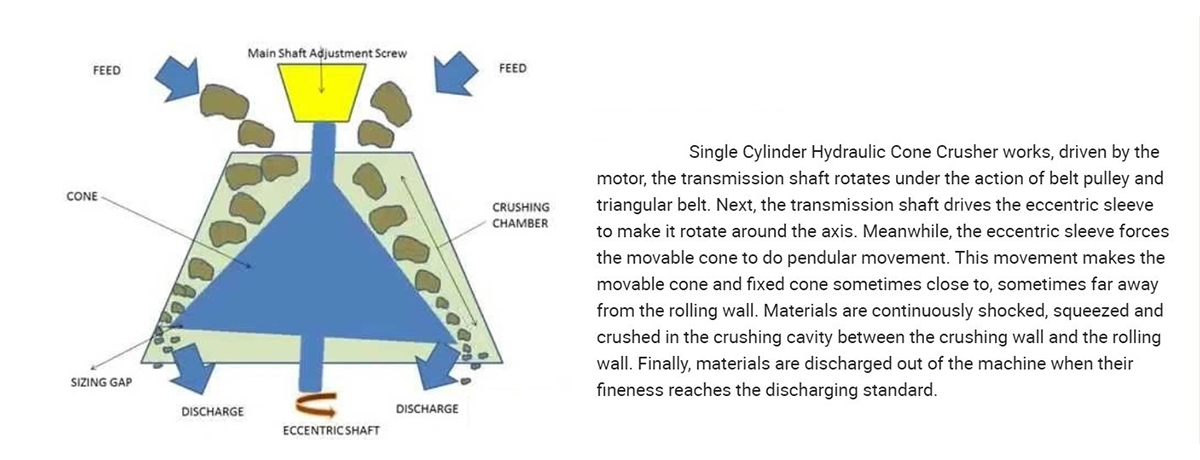

The single cylinder hydraulic cone crusher has features of simple structure, stable and reliable operation, easy maintenace. It is the ideal crusher machine for middle crushing or fine crushing of rocks or minerals.

The single cylinder hydraulic cone crusher has features of simple structure, stable and reliable operation, easy maintenace. It is the ideal crusher machine for middle crushing or fine crushing of rocks or minerals.| Model | VSH820 | VSH830 | VSH840 | VSH860 | VSH870 | VSH880 | VSH885 | VSS820 | VSS830 | VSS840 | VSS860 |

| Power (kW) | 90 | 160 | 250 | 315 | 500 | 750 | 750 | 90 | 160 | 250 | 315 |

| Cavity Type | Max Feeding Size (mm) | Max Feeding Size (mm) | Max Feeding Size (mm) | Max Feeding Size (mm) | Max Feeding Size (mm) | Max Feeding Size (mm) | Max Feeding Size (mm) | Max Feeding Size (mm) | Max Feeding Size (mm) | Max Feeding Size (mm) | Max Feeding Size (mm) |

| EC | 135 | 190 | 215 | 275 | 300 | 370 | 240 | 360 | 450 | 560 | |

| C | 90 | 145 | 175 | 215 | 240 | 330 | 200 | 300 | 400 | 500 | |

| MC | 115 | 140 | 175 | 195 | 300 | ||||||

| M | 65 | 90 | 110 | 135 | 155 | 230 | |||||

| MF | 50 | 75 | 85 | 115 | 100 | 160 | |||||

| F | 38 | 50 | 70 | 85 | 90 | 120 | |||||

| EF | 28 | 35 | 38 | 65 | 80 | 85 | |||||

| EFX | 100 | ||||||||||

| EEF | 75 |